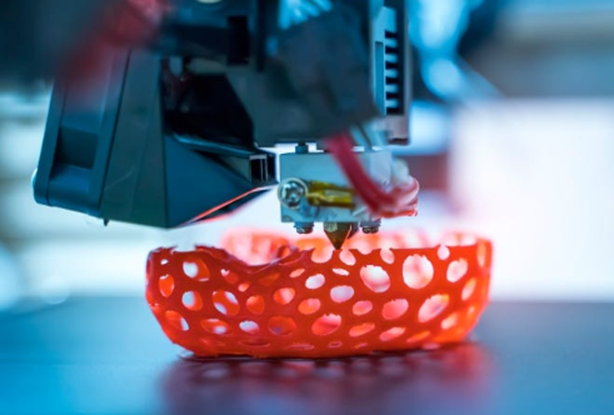

Where Are 3D Printers Commonly Used?

Over the past few decades, 3D printing technology has made significant strides, transforming the way we manufacture and create various objects. Initially developed for rapid prototyping in the aerospace and automotive industries, 3D printing has now found its way into countless sectors, offering innovative solutions and disrupting traditional manufacturing processes. In this article, we will explore the diverse applications of 3D printing and where it is commonly used.

Table of Contents

1. Healthcare and Medicine

One of the most promising and rapidly expanding fields for 3D printing is healthcare and medicine. Here are some common applications:

a. Prosthetics and Orthopedics: 3D printing allows for the customization of prosthetic limbs and orthopedic implants to match a patient’s unique anatomy, improving comfort and functionality.

b. Dental: Dentistry has embraced 3D printing for creating crowns, bridges, and even orthodontic devices with high precision and speed.

c. Tissue and Organ Printing: Scientists are investigating 3D bioprinting as a means to generate tissues and organs for potential transplantation, which could lead to a significant transformation in the realm of regenerative medicine.

2. Aerospace and Automotive Industries

The aerospace and automotive industries have been pioneers in adopting 3D printing technology. Some common applications include:

a. Rapid Prototyping: 3D printing is used to create quick prototypes of parts and components, reducing development time and costs.

b. Lightweight Structures: Aerospace companies use 3D printing to manufacture lightweight and complex components, improving fuel efficiency and performance.

c. Spare Parts: In remote or isolated locations, the 3d printer can produce spare parts on-demand, minimizing downtime.

3. Architecture and Construction

In the realm of architecture and construction, 3D printing has emerged as a game-changer. Some common applications include:

a. Architectural Models: Architects use 3D printing to create intricate and detailed architectural models, helping clients visualize their designs.

b. Customized Building Components: Some construction companies employ 3D printing to produce custom building components, such as facades, panels, and even entire houses.

4. Education and Research

Educational institutions and research facilities have embraced 3D printing for various purposes:

a. Educational Tools: 3D printers are used in classrooms to teach students about design, engineering, and problem-solving.

b. Prototyping in Research: Researchers across disciplines use 3D printing to create prototypes for experiments and studies, accelerating the pace of innovation.

5. Consumer Products and Gadgets

The consumer industry has seen a surge in 3D printing applications, especially for personalized and customizable items:

a. Jewelry and Fashion: 3D printing enables the creation of unique, personalized jewelry and fashion accessories.

b. Home Decor: Consumers can purchase 3D-printed home decor items like vases, lampshades, and decorative sculptures.

6. Food Industry

Innovations in 3D printing have extended to the culinary world:

a. Food Prototyping: Chefs and food scientists use 3D printing to experiment with new food designs and presentations.

b. Custom Cake Toppers: Bakeries and confectioneries create intricate cake toppers and decorations using edible 3D printing.

7. Electronics and Circuitry

3D printing has found applications in electronics manufacturing:

a. Circuit Boards: 3D printers can produce intricate circuit boards and casings for electronic devices.

b. Prototyping Electronics: Engineers use 3D printing to prototype and test electronic components quickly.

Conclusion

3D printing technology has permeated diverse sectors, revolutionizing the way we manufacture, create, and innovate. From healthcare and aerospace to education and consumer goods, the applications of 3D printers continue to expand. As technology evolves and becomes more accessible, we can expect even more industries to harness its capabilities to offer customization, rapid prototyping, and efficient production, reshaping industries and pushing the boundaries of what is possible in manufacturing and design.