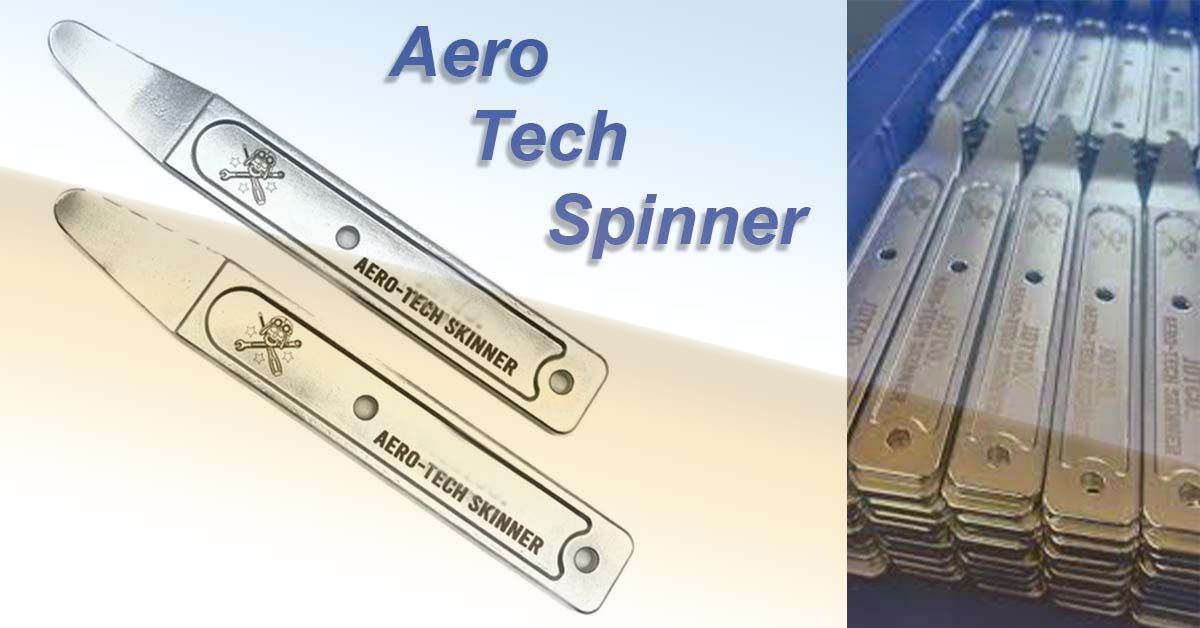

Aero Tech Skinner: Changing the Face of Precision Cutting in the Aerospace Industry

The aerospace industry has always been at the forefront of technological advancements, constantly pushing the boundaries of innovation to achieve greater precision and efficiency. One such breakthrough that is revolutionizing precision cutting in the aerospace industry is the Aero Tech Skinner. This cutting-edge tool has transformed the way aircraft components are manufactured, significantly enhancing productivity, quality, and cost-effectiveness.

Table of Contents

Unparalleled Precision

When it comes to precision cutting, every fraction of an inch matters in the aerospace industry. The Aero Tech Skinner is designed to deliver unparalleled precision, enabling manufacturers to achieve the tightest tolerances required for aerospace applications. The tool incorporates advanced laser-guided technology, ensuring precise and consistent cutting paths, even for the most intricate designs.

Versatility & Adaptability

The Aero Tech Skinner stands out for its versatility and adaptability, making it suitable for a wide range of materials used in the aerospace industry, including metals, composites, and advanced alloys. Its cutting capabilities extend to various thicknesses and geometries, making it an indispensable tool for manufacturing components like fuselage panels, wing skins, and structural frames.

Streamlined Workflow

With traditional cutting methods, the aerospace industry faced numerous challenges, including time-consuming setups, manual adjustments, and excessive scrap generation. The Aero Tech Skinner streamlines the manufacturing workflow by reducing setup times and eliminating the need for manual adjustments. Its automated features allow for quick and seamless transitions between different cutting operations, optimizing productivity and minimizing downtime.

Enhanced Safety

Safety is of utmost importance in the aerospace industry, and the Aero Tech Skinner prioritizes this aspect. The tool is equipped with comprehensive safety features, including laser safety systems, sensors for detecting potential hazards, and emergency stop mechanisms. These safeguards ensure that operators can work with confidence and minimize the risk of accidents or injuries.

Cost Efficiency

In addition to its precision and productivity benefits, the Aero Tech Skinner offers substantial cost savings to aerospace manufacturers. By minimizing material waste through precise cutting, companies can significantly reduce their production costs. Moreover, the tool’s automated processes and reduced setup times result in higher throughput and increased overall efficiency, translating into significant savings in labor costs.

Future Potential & Industry Impact

The Aero Tech Skinner is just the beginning of a new era in precision cutting technology for the aerospace industry. As research and development continue, we can expect further advancements that will push the boundaries of what is possible in terms of accuracy, speed, and versatility. This technology is set to transform the aerospace manufacturing landscape, enabling the production of lighter, stronger, and more fuel-efficient aircraft.

Conclusion

The Aero Tech Skinner represents a major leap forward in precision cutting for the aerospace industry. Its unmatched precision, versatility, streamlined workflow, enhanced safety features, and cost efficiency make it a game-changer for manufacturers. As this technology continues to evolve, it will undoubtedly shape the future of aerospace manufacturing, driving innovation and propelling the industry toward new heights. With the Aero Tech Skinner, the possibilities for creating high-quality aircraft components are virtually limitless.